Products

Autofocus function Triaxial spiral scanning system EG-DL240-400-Z5-T

Product Overview

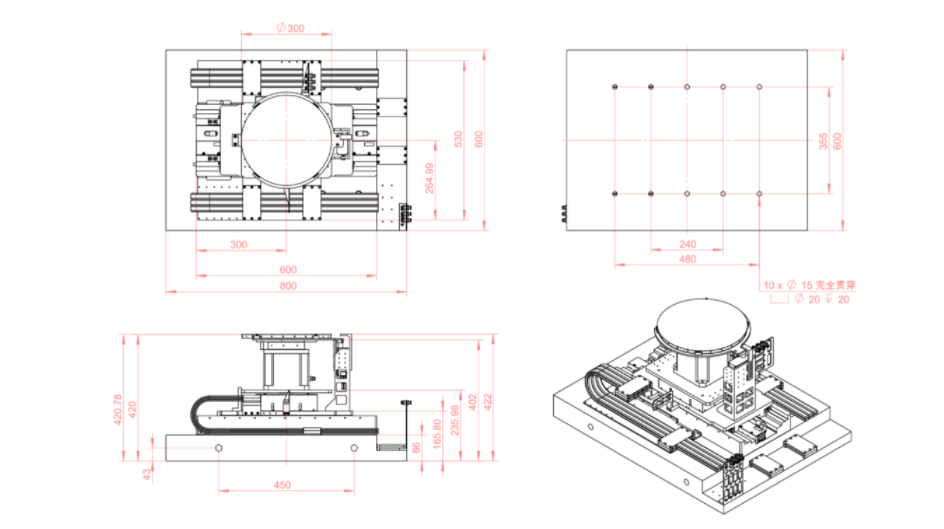

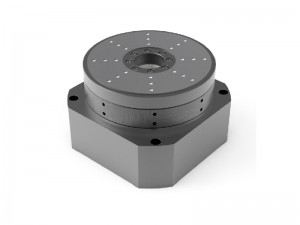

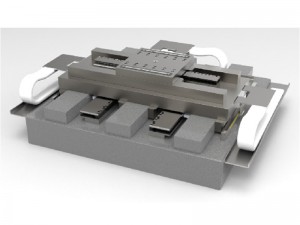

The EG-DL240-400-Z5-T is a high-performance three-axis helical scanning system that integrates the X-axis (linear motion), Z-axis (linear motion), and T-axis (rotational motion) to form a three-dimensional helical scanning system. The system uses linear motors to drive the X and Z axes, equipped with high-precision crossed roller guides and a Z-axis cylinder counterweight; the T-axis uses direct-drive rotary motor technology and integrates a high-resolution optical encoder. The overall design achieves precise three-dimensional Archimedean spiral trajectory motion control and supports autofocus, making it particularly suitable for industrial scenarios with stringent requirements for helical scanning accuracy and multi-dimensional control. The system achieves a synthetic linear velocity of up to 2000 mm/s, and the maximum T-axis speed reaches 6000 rpm, ensuring high-speed and efficient operation.

Applicable Scenarios

The EG-DL240-400-Z5-T system boasts significant advantages in semiconductor wafer defect detection and surface contour scanning. Its high-precision spiral scanning capability and autofocus function make it an ideal solution for wafer manufacturing and quality inspection processes.

Microscopic Defect Detection: The system performs high-speed spiral trajectory scanning to accurately identify microscopic defects on the wafer surface (such as scratches, particle contamination, and uneven etching). Combined with ±200nm absolute positioning accuracy on the X and Z axes and high resolution on the T axis, it can achieve sub-micron level defect capture, significantly improving wafer yield.

Surface Contour Measurement: Through 3D spiral scanning and autofocus, the system can generate real-time 3D contour maps of the wafer surface, suitable for thin film thickness measurement, step height analysis, and topology detection. Z-axis cylinder counterweight and low-runout design ensure stable contact during high-speed scanning, avoiding damage to brittle wafers.

In addition to wafer inspection, the system is also suitable for other high-precision applications:

|

Model |

X |

Z |

T |

|

| Travel | 400mm | 5mm | 360° 连续 | |

| Accuracy | ±200 nm | ±200 nm | ±1 arc sec | |

| Bi-Repeatability | ±150 nm | ±100 nm | ±0.5 arc sec | |

| Pitch | 14 arc sec | 20 arc sec | ||

| Yaw | 12 arc sec | 20 arc sec | ||

| Straightness | ±2 μm | ±2 μm | ||

| Flatness | ±2 μm | |||

| Axial Error Motion | 200 nm | |||

| Radial Error Motion | 200 nm | |||

| Maximum Speed① | 800 mm/s | 4 mm/s | 6000 rpm | |

| Maximum Acceleration | 1 g (No load) | 1 g (No load) | 5400 ° /s2 | |

| ContinuousForce①( Torque-Continuous) | 81.8 N | 24.4 N | 3.5 N·m | |

| Peak Force(Torque-Peak) | 506.6 N | 170.4 N | 10.5 N·m | |

| Load Capacity | Horizontal( Axis) | 30 kg | 10 kg | 10 kg |

| Side( Radial) | 20 kg | 2 kg | ||

| Wedge Ratio | 12:1 | |||

| Stage Mass(No Motor) | 26 kg | 4.5 kg | 7.4 kg | |

| Resolution | 1 nm | 1 nm | 0.1 arc sec | |

| Minimum Incremental step② | 10 nm | 5 nm | 0.2 arc sec | |

| In Position Stability② | ±10 nm | ±5 nm | ±0.2 arc sec | |

| Operating Pressure⑤ | 5.5bar(Dry air is recommended; water and oil should be filtered out; dust particles should be filtered to below 0.5μm.) | |||

| Material | Aluminium | |||

| MTBF | 30,000 Hours | |||